Fast Features:

1. Suitable for heating forming materials, PP, PS, PET, PVC, PLA etc.

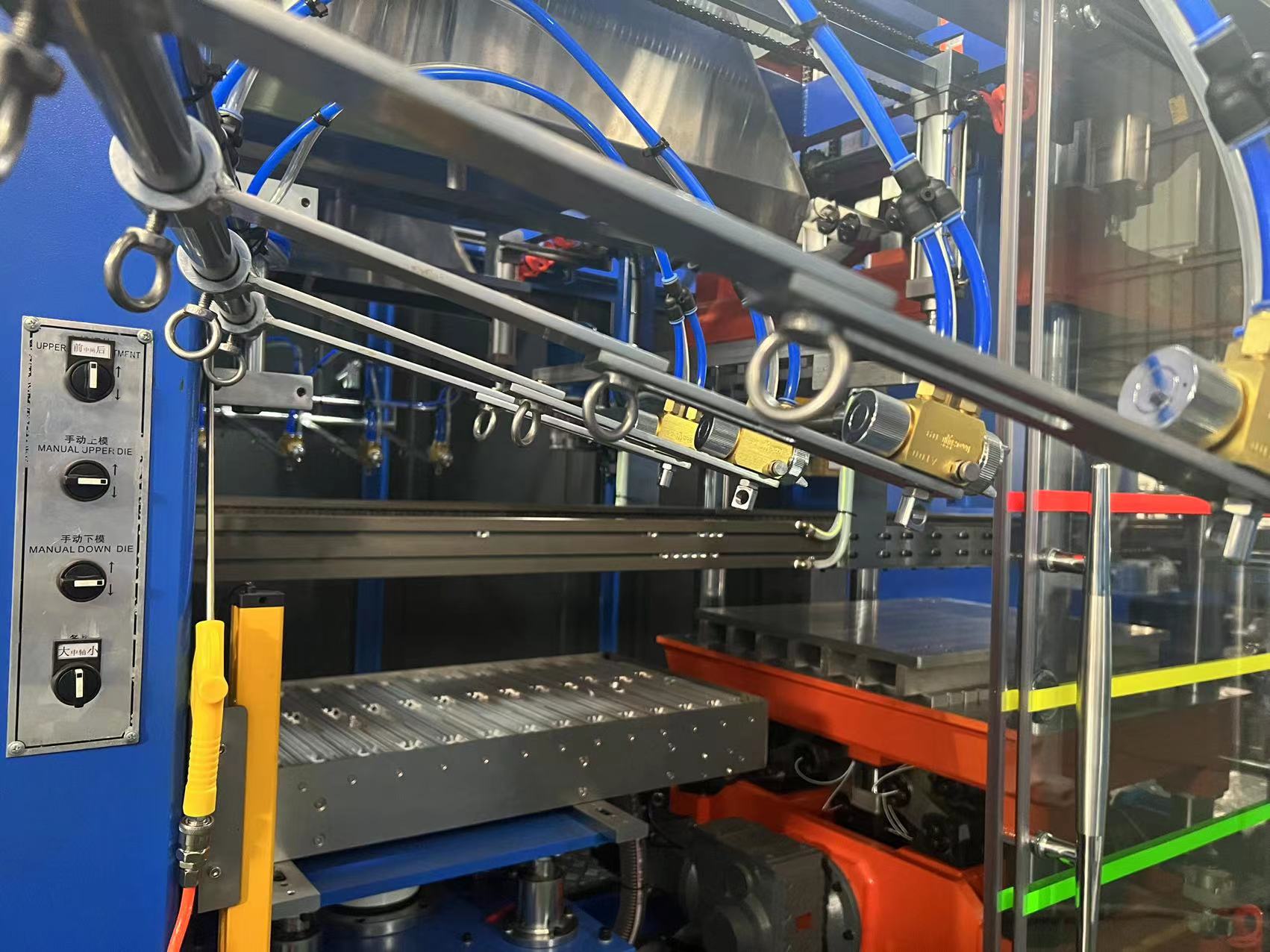

2.Fully auto production line, including Heating stove, Negetive vaccum forming, Cutting Station, and Stacking station.

3. Delta PLC; Full servo.

Full 6 sets of Delta precise control, 1xpulling, 1x forming, 2xcutting, 1/2xstacking (Robot arm stacking 2 servos)

4.Max forming size: 710*900mm for high production quantity.

5.Optional: Robot arm stacking or Downward stacking, or both together for choice.

6. Most advantages is Low cost Available moulds to install: normal vaccum forming machine mould(Plastic, plaster, aluminum), normal cutting machine wooden cutting die. Versatile adjusted stacking/Robot arm.

7.Hero Brand Heating control, Sweden heating brick, infrared ceramic heater,2-stage heating for upper and lower furnaces.

8. HONGGANG brand cutting station, iron cast, steady for long time cutting.

9. Based on structure of Dongxing Brand over 25 years of making thermoforming machine experience, as well rich experience in thermoforming control system, and heating sytem.

10. Multi-language support of operation.

11. Full automatic working, Less man power.

12. Chain adjustment fully flexibility in 3 positions of 3 motor controlled and adjustment.

13. Moulds platfoam can be manual or automatic changing, 50mm as changeable range, to reduce the working time and raise the production speed.

Usages:

DX-FY series can be used as traditional vaccum forming machine, and sharing moulds of traditional vaccum forming machine and die cutting machine, so the normal trays, blisters, blister boxes, and containers can be made and widely used for packagings of all size of packing containers for foods, cosmetics, toys, electricities, textiles, drugs, hardware tools, household appliances, handicrafts.

Packaging of electronics, stationery, toys, small household appliances, handicrafts, cosmetics and other products, the main products are: trays, blister, blister boxes, plastic bags.

Detailed pictures:

Parameters: