B. The Cutting Parts of A Cutting Solution

One cutting solution includes 3 parts of feeding part, cutting part and despatching parts.

Here is the feeding parts introduction, we have 8 kinds of different feeding systems for kinds of materials to feed.

Today we are going to introduce the cutting part.

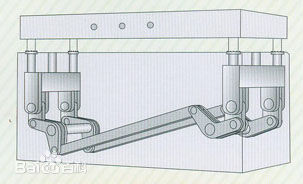

Structure

Cutting part is the cutting machine, as well the cutting body. Our brand cutting machine structure is hydraulic type, with double-cylinders and four -column in both sides, center is the cutting area, based on the auto-balance structure, which is popular and widely adopted in cutting press machine market for over 30 years. Such kind of structure is flexible, steady, precise for cutting, compare to machanical electric power producer, it helps to prolong the whole machine and parts working.

B. Five kinds of cutting system

B.1 Full beam/fixed head beam cutting press: manual type; double table type

Have to say, within 1000 sets of HONGGANG brand machines made in one year, there are 950 sets of full beam cutting press machine. Over the 18 years, HONGGANG factory manufacturers full head cutting press with different feeding systesms, from 30 tons to 800 tons, different cutting areas. The full beam cutting press is so popular because it can be fit with different feeding systems, such as full belt table, double sides table, belt-clip table and so con. Also it's powerful with big pressure for big cutting dies, cutting full sheet, large sheet by one time, and highly raise the output speed, such as for car interior, foam packing, plastic blister packing products die cutting. For reference:

Manual full head cutting press machine.

Packing foam cutting press machine playlist

Plastic packing cutting machine playlist

B.2 Full beam with running 1 die/2 dies cutting machine

Such kind of cutting designed for small profucts for shoes or bags such of leather products. It can be fixed one die moving from left to right, as well two different size dies, when big dies finishes the cutting, the small die will follow up to cut on the empty space for saving the materials.

B.4 Rotary travel head cutting machine.

Rotary travel head cutting machine is based on the manual type travel head cutting press. With rotary head, it can change the cutting die direction and make the cutting patterns close, to realize the materials saving. However, no matter travel head or rotary travel head, it's fading out of the history because of faster and bigger machine of full head cutting full sheet, instead small dies. Anyway, it's still used in small workshops and factories.

B.5 Receding head cutting press.

Receding head cutting press is with the cutting head forward and backward running. When after cutting, the cutting head will go up and run backward out of cutting area, to make the cutting area have good vision and more safe for picking up and arranging materials. Because of such of structure, receding head cutting press is still popular in European countries, Japanese for leather goods industry, as well automobile trimmings fabricating.

Well, after knowing the different cutting machines, how to select the cutting part? Different cutting type seems easy, anyway, just depending on the operation, it's easy to get which way you need. But it's not an easy thing when it comes to the cutting pressure and cutting areas.

Cutting pressure & cutting area

These two specifications are the main data for cutting press choosing.

Honggang factory has from 30 tons to 800 tons cutting pressure for the full head beam cutting press, max 2600x1600mm cutting area made. Each level pressure and cutting area as customized, with much different price gap. In case of too large expense, as well to avoid the machine not enough pressure, it is so important to discuss the production details, from materials ranges, product ranges, cutting die designs and output speed requirements.

Have to say, even for one kind materials/products, such as cleaning sponge, we have over 6 models as sponge cutting machines, used by different customers, from manual, semi-auto to automatic, from small 30 tons to 250 tons:

Even for foam packing, blister packing, also the cutting pressure still varies 30 tons to 200 tons, 300 tons for different factories production requirement.

Anyway, contact us when you have any doubts! Talk to us with your production requirments!

6/8/2021

Tina Chen

Email: sales@hgcuttingsystems.com

What'sapp/Wechat: +8615918086545

2,Fenghuang dadao, National Eco-industry Park, Nanhai,Foshan,Guangdong,China.528000

Youtube videos playlist: Honggang Cutting Machine-China hydraulic cutting machine manufacturer/supplier - YouTube

Website: Honggang Cutting Machine-Die Cutting Press Manufacturer China