Industry:

Auto parts (air cushion), bags, shoes, handbags, stationery, breathable material, advertising paper products and other industries.

Materials:

Punching for Cow skin, artificial leather, PU, EVA, PVC, plastic, all kinds of cloth, paper, leather accessories, curtain, automobile leather chair, etc.

| Model | HG-H7050-8 | HG-S7050-8 | HG-S7050-10 |

| Pressure | 5-8kgf / cm2 | ||

| Power | 1.8kw | ||

| Punching number | 2 groups*4 | 2 groups*4 | 2 groups*5 |

| Punching area | 500mm*700mm*2 | ||

| Thickness of the leather | 0.6-8mm | ||

| Punching range | 0.6-14mm | ||

| Punching speed |

600-980 holes/ minutes*2 groups |

500-700 holes/ minutes*2 groups |

500-700 holes/ minutes*2 groups |

| Weight | 1000kg | 1100kg | 1100kg |

| Diemension | 1750mm*1850mm*1560mm | ||

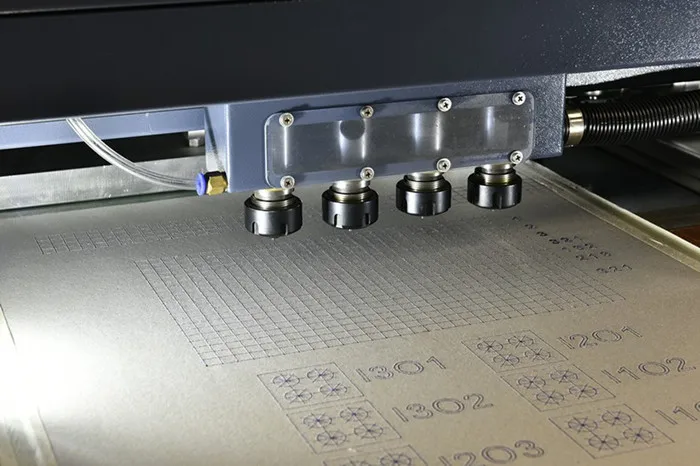

1.CNC punching machine and leather machine adopts whole steel structure, to deal with the stress, precision machining, good stability, high rigidity; Flexible transmission mechanism adopts imported ball screw, nut precision. CNC leather punching machine adopts flexible control tool, cutting tool can be set rotation according to need or not rotating, independent development of processing software tool Angie of arbitrary switching; All kinds of cutting tools, can be combined on the leather work out a rich variety of patterns.

2.Computer typesetting automatic punching, processing after the completion of automatic back in situ, high efficiency, safe and reliable.

3.Pieces with different sizes of different punch, materials can be used in the small design of complex, solved the difficult problem of small design mold.

4.Pieces can be in a small area of any parts for punching, operation is flexible and convenient.

5.A pair of mold to blunt variety, and can through the computer simulation imitation.

6.Shock wave and punch radius: 0.5 -9 mm.

7.Shock wave stiletto is of good quality, low noise, no damage of material, not burning, not black. Impact power adopts motor as a driving force, after the processing of leather surface level off, compared with laser machine punching machine, no burning, black phenomenon.

8.Pieces of pattern design and changed by software and punch, without changing the mechanical mould, convenient and quick operation.

♦ Pre-sale service:

Advisory services: our distributors or sales staff to guide you processing products, I will provide reference and Suggestions for you, let you really understand the required mechanical, and to provide you with relevant industry information, help customers to understand the latest frontier dynamic industry.

♦ After-sales service:

(1) Free installation debugging equipment;

(2) For you free of charge training employees;

(3) Free of charge to provide you with relevant industry information;

(4) Free overseas warranty.