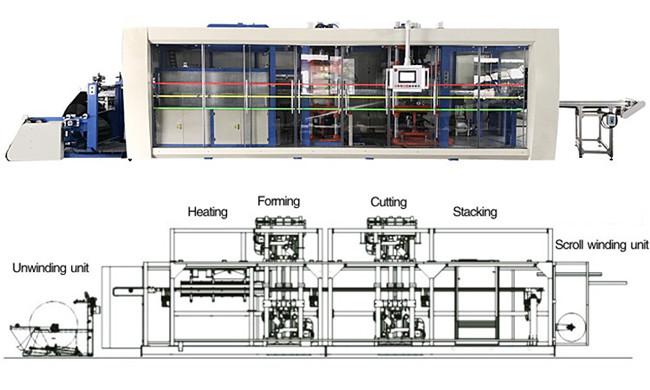

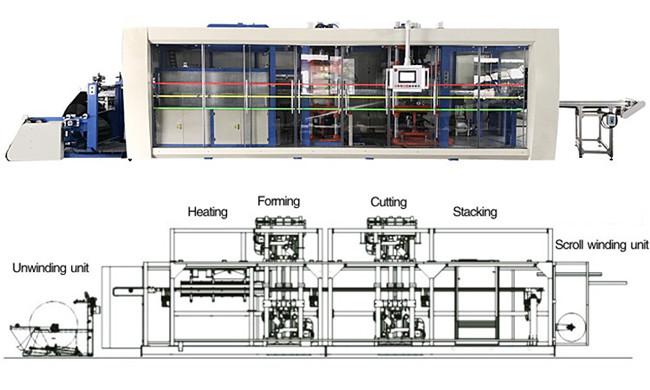

1. 3/4 Stations Positive and negative pressure thermoforming machine

1/ Three stations: positive and negative pressure forming, cutting, stacking

2/Forming upper mold core servo control

3/ Outer eight models of front loading mold

5/ Automatic mold clamping device

6/ Chain track eight-character function (applicable to PP, full degradation Material with high material sag)

7/ German Beckhoff controller, servo drive system is Swiss ABB (motion control absolute value mode)

8/Zhuanggu temperature control (computer digital temperature control, one-to-one precise temperature control temperature difference positive and negative 0.5 degrees, intelligent temperature control and 20% energy saving)

9/Chain rail electronic ruler adjustment

2. Delivery time: delivery after 60 working days from the date of receiving the deposit;

3. Payment Terms: 30% deposit, after the completion of the machine, Party A will go to our factory to test and accept, and 70% will be paid before delivery.

4. Machine Specification:

This machine is desined for producing all size packaging containers, in open-type with thin wall, by using rol-sheet, under high-speed vacum suction foming pocessingg The produts made by this machine can be used for the package of foods, tourist-good, textile, medical,toy, cosmetic, electrical elements and daily used hard ware, etc.

Suitable Sheet

PP, PS, PET, PVC, OPS, degradable materials, PLA. etc.

Structure Features

◆Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC.Touch screen makes the operation convenient and easy.

◆Forming type: vacuum and /or pressure forming.

◆Servo motor feeding, feeding length can be step-less adjusted, High speed and accurate.

◆Up heater with 4 sections heating, down heater with 3 sections heating. With sheet edge preheating.

u Heater with itellctual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won't be effected by outer voltage

u Forming and cutting funtion in the same station, controlled by servo motor, high cutting precision.

◆Stacking type: downward stacking/ manipulator stacking.

u With quick changing mould system, produts details and running data memorization function,more efficient.

u Feeding width can be synchronously or independently adjusted in electrical way.

u Heater automatically push-out when the sheet is over heated.

◆Auto roll sheet loading, reduce the working load.

Data:Model:D&M-60

|

No.

|

Term name description

|

Technical Parameters

|

|

1

|

Applicable raw materials

|

PP, PS, PET, PVC, OPS, degradable materials, PLA. etc.

|

|

2

|

Forming method

|

Positive and negative pressure forming

|

|

3

|

Maximum forming mold area

|

Width 780×length 600mm

|

|

4

|

Minimum molding die area

|

420×300mm

|

|

5

|

Maximum sheet width

|

810mm

|

|

6

|

Applicable sheet thickness

|

0.15-2.0mm

|

|

7

|

Maximum punching area

|

780×600mm

|

|

8

|

Cutting knife line

|

8M knife line

|

|

9

|

Maximum opening and closing stroke of forming mold

|

150mm

|

|

10

|

Molded product height

|

130mm

|

|

11

|

Stacking mechanism

|

Hanging point stacking

|

|

12

|

Rated power of whole machine

|

120kw

|

|

13

|

Power consumption

|

25-50kw

|

|

14

|

Power access

|

380V/50HZ (three-phase five-wire)

|

|

15

|

Total Weight

|

16,000kg

|

|

16

|

physical dimension

|

L13 m×W2.4m×H2.6m

|

|

17

|

Maximum sheet material roll diameter

|

1100mm (within 500KG)

|

|

18

|

Work efficiency

|

40 molds/minute (depending on material thickness)

|

|

19

|

cooling method

|

The mold is cooled by circulating water

|

ain configuration instructions

|

No.

|

Name

|

Brand

|

|

Control System

|

Control System

|

Beckhoff System

|

|

Programmable Controller (PLC)

|

Beckhoff System

|

|

Touch display

|

15 inch color touch monitor

|

|

Pull tab servo system

|

Pull tab servo system

|

Switzerland ABB

|

|

Pull tab gearbox

|

High precision planetary reducer

|

|

Chain guide

|

Aerospace aluminum alloy surface hard oxygen treatment

|

|

Pull tab chain

|

Taiwan KMC (double-row guide chain)

|

|

Rail (beam) cooling system

|

The whole beam is cooled by water (circulating water)

|

|

Rail adjustment

|

The guide rail is electrically adjusted and can be adjusted in one direction

|

|

Drive System

|

Cycles

|

40 times/minute

|

|

Forming Servo System

|

Switzerland ABB 5.5kw

|

|

Punching and cutting servo system

|

Switzerland ABB 5.5+7.5kw

|

|

Stack Servo System

|

Switzerland ABB

|

|

Station structure

|

Cam structure

|

|

Heating system

|

Intelligent temperature control system

|

Zhuanggu (hero) one control one computer digital temperature control

|

|

Far infrared ceramic heater

|

Japan Yamatake temperature measurement module

|

|

Hot stove (stainless steel hot stove)

|

Ceramic heating brick (Sweden KANTHAL imported heating wire)

|

|

cooling system

|

cooling system

|

The length of the heating furnace is 3 times of the forming length, the upper and lower furnaces are heated, and the lower furnace has a protective steel mesh. High temperature resistant wire, with current overload protection.

|

|

cooling method

|

8HP air-cooled chiller

|

|

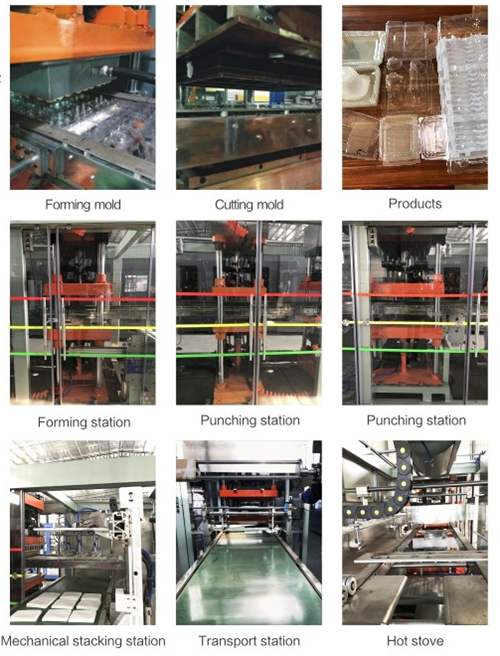

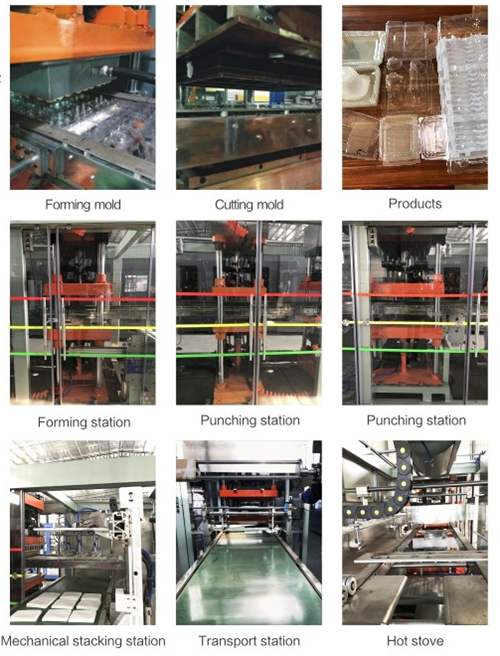

Forming station

|

Forming station

|

The mold is cooled by circulating water (6 water inlets and outlets)

|

|

Positive air pressure valve

|

The height of the upper mold table can be adjusted by 50mm

|

|

Bottom wind

|

Japan SMC ultra-high-speed response fluid valve

|

|

Install the device

|

Bottom air adopts atmospheric volume valve

|

|

Vacuum pump

|

German Weili 100M3/H (with large flow vacuum valve)

|

|

Cutting station Cutting part

|

Cutting part

|

Servo direct blanking; the height of the forming upper die table can be adjusted by 50mm

|

|

Install the device

|

Equipped with safety hooks for easy operation

|

|

Stacking system

|

Automatic points, automatic stacking function

|

|

Winding system

|

Frequency conversion automatic winding function, adjustable torque function

|

|

Security system

|

1. 1. Equipped with safety grating devices on the left and right sides

|

|

Lubrication system

|

2. Part of the machine is equipped with an emergency stop device

|

|

Feeding system

|

3. Leakage, overload safety switch

|

|

Electrical appliances

|

The guide rail is equipped with a needle valve type oil cup lubrication system

|

|

Double material bar automatic mechanical feeding roll device, roll diameter 1100mm, can bear 500KG

|

|

AC contactor Japan Fuji

|

|

Proximity switch Japan Omron

|

|

Switching power supply MEAN WELL

|

5.Product sample

Detailed Specifications:

|

Term

|

HGDX-7185 Fully Auto Positive and Negative Thermoforming Punching Machine (Full-Servo)

|

|

Bases Data:

|

|

|

Sheet length

|

410mm-850mmadjusted

|

|

Sheet width

|

410mm-710mmadjusted

|

|

Max. Formed Area

|

710x850mm

|

|

Availability Punching Area(Max)

|

710x850mm

|

|

Sheet height

|

1mm-120mm

|

|

Negative formed part height

|

130mm

|

|

Positive formed part height

|

130mm

|

|

Sheet thickness

|

0.15mm-2.0mm

|

|

Furnace moving

|

Move out from the side of hot stove

|

|

Suitable power

|

3 phases 380V 50HZ/

|

|

Installed Power

|

100KW

|

|

Dimension

|

11×2.3×2.5m

|

|

Electric feeding rack

|

1.8m*1.3m

|

|

Conveyor

|

3.5m*1.1m

|

|

Whole Weight

|

12 tons

|

|

Working Weight

|

12tons

|

|

Machine frame

|

Main fram: 150*75*6 FANGTONG

|

|

|

Conveyor: Stainless steel from FANGTONG

|

|

|

Material box: No.10 International Channel Steel

|

|

|

Air cylinder: NO. 35 Lighting plate electroplating

|

|

Electric Parts:

|

|

|

|

PLC

|

DELTA

|

214-1AD23

|

|

PCL MODUEL

|

223-1BH22

|

|

|

PLC MODULE

|

222-1BH22

|

12INCH

|

|

Touch screen

|

DELTA

|

|

|

Temperature Control module

|

DELTA

|

|

|

potentiometer

|

2W 1K Omron

|

|

|

Relay

|

JAPAN IDEC

|

|

|

Contactor

|

FUJI Electric

|

|

|

Air switch

|

JAPAN MITSUBISHI

|

|

Heating system

|

Intelligent temperature control

|

|

Heating brick

|

Energy saving heating brick

|

Down furnace 4*12rows, 800W/pcs, Up furnace 6*20rows 500W/pcs.

Furnace effective area 7350*2600mm

|

|

Sheet pulling

|

7.5 DELTA servo

|

|

|

Cooling system

|

Beam frame chassis through water

|

|

Drive part

|

1,Caterpillar imported flat light chain processing, surface plating Hard nobelium.

|

|

|

2.Sprocket High quality steel tooth surface annealing treatment.

|

|

|

3.The visible parts, the whole machine such as cylinder plate, caterpillar, spindle and all surface rigidity nobelium

|

|

|

4. Electric track adjustment (before and after synchronization, accurate regulation, convenient operation)

|

|

|

5. Electric feeding rack (150 kg heavy material can be easily handled by one person)

|

|

Cooling machine

|

Two Fans and 5 HP water cooling machine

|

|

|

|

|

Vacuum system:

|

|

|

Vacuum Pump

|

100 Busch Oil Ring Pump

|

|

Vacuum box

|

0.3CBM

|

|

Vacuum valve

|

Selt Made Double Valve

|

|

|

|

|

Drive system:

|

|

|

Motor

|

Pulling 7.5KW DELTA SERVO

|

|

|

DELTA Driver

|

|

Solenoid valve

|

Main valve Japan CKD

|

|

Hydraulic valve

|

Germany Rexroth

|

|

Air Liquid Pump

|

Jingtuo Jinan China

|

|

Two way valve

|

Germany ABL

|

|

Five way valve

|

Japan CKD

|

|

Positive pressure valve

|

Japan SMC

|

|

Air cylinder

|

High wear-resistant cylinder, Zhicheng brand, from Zhaoqing

|

|

Up mold

|

4.0KW Servo motor ,clamping force 20 tons

|

|

Down mold

|

4.0KW Servo motor

|

|

Up cutting board

|

4.0KW Servo motor, clamping force 20 tons

|

|

Down cutting board

|

4.0KW Servo motor

|

|

Punching board

|

120*10 double-cylinder, gas liquid booster pump drive, pressure 60 tons.

|

|

Put sheet

|

50*125 standard cylinder

|

|

Furnace

|

80*830 un-standard cylinder (High wear-resistant cylinder, Zhaoqing Zhicheng)

|

|

Vacuum valve

|

40*50

|

|

Pneumatic joint and hose

|

Imported “Yamas”

|

10. Machine introduction

1) Major Function

1. negative pressure molding device,

2.vacuum forming device,

3. touch screen computer temperature control module of function,

4. gas control device,

5. cooling device,

6. knife mold, mold temperature control function,

7. automatic punching and cutting function, automatic counting function,

8. Stacking after cutting.

9.edge automatic rolling function,

10. safety protection device

2) Advantage of Machine

Machine in the production of the highest speed of up to a.3 seconds / mode, b,all servo control system, c,coupled with the overall advanced automation system, can be adapted to a variety of sheet. The model has the most humane mold replacement structure, greatly shorten the time to change mode, advanced heating system, the intelligent module temperature control, fast response, short time, to strive for the highest efficiency, low cost. The new type of electric furnace, the upper and lower furnace heating frame all use stainless steel with heat insulation plate material design, weight, low cost, fast heat, simple appearance. The heater adopts the Sino British joint venture ceramic infrared radiation heater, and the imported solid state relay has no contact output, which ensures fast heating up, high precision, stable and temperature control error.

The sheet feeding chain adopts imported double toothed roller chain, integral Aluminum Alloy chain guide, compact structure, guide the cooling water, high cooling efficiency, internal circulation water, save water. Each servo motor is provided with a thermal protection device, in order to prevent the servo motor from overload and over current and the equipment is damaged due to the long-term operation, and the motor is provided with an over current protection device.

Positive and negative pressure multi-stations machine is introduced German latest research and development of technology for packaging, food, electronics and other industries innovative products, this machine has the heating and molding, punching and cutting, stacking and counting four station automatic function, can adapt to the plastic packaging products PLA, PS, PET, PP, PVS, ABS etc. materials of all kinds of bowl, cover, box, tray, dish, medicine and industry, this machine is widely used, strong versatility, positive pressure and negative pressure molding machine speed, low energy consumption, low noise, high degree of safety and sanitation, convenient operation and maintenance and other advantages of the majority of customer trust.

11. Company introduction

Dongxing is one thermoforming machine brand of Honggang company specially for fully auto Three stations of thermoforming + Cutting + Stacking machine for blister products, such as food tray, fruit tray, Package box, electric package tray, cup, lid, bowl, disposable fast food box and so on. Dongxing thermoforming machine mainly adapts Japanese Operation System.

Foshan Add: 2# Fenghuang Dadao, National-Eco Industrial Park, Danzao Town, Nanhai District, Foshan City, Guangdong, China.. Manufacture cutting machine and main part to Dongxing in Dongguan.

Dongguan Add: NO.448 Lilang Road Langxia Village Qiaotou Town, Dongguan City, Guangdong, China. 523532. Manufacture thermoforming machine.